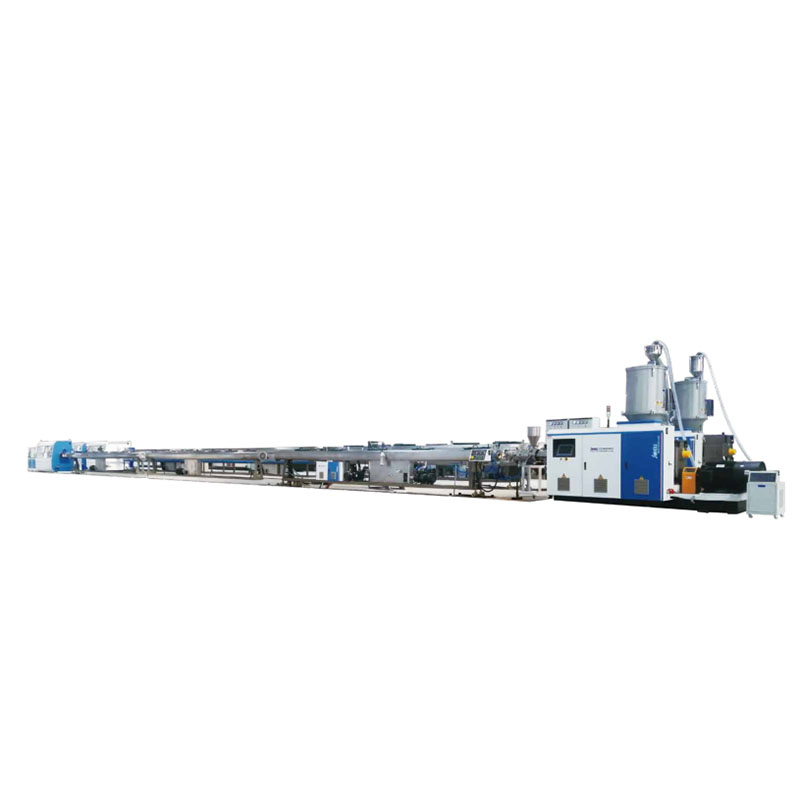

HDPE Pipe Extrusion Line na-echekwa ike dị elu

Isi Nka na ụzụ Parameter

Arụmọrụ & Uru

Ụlọ ọrụ anyị ọhụrụ nnyocha na mmepe nke ike-azọpụta elu-ọsọ mmepụta akara, adabara elu-ọsọ polyolefin ọkpọkọ extrusion. 35% nchekwa ike yana mmụba 1x na nrụpụta nrụpụta. Ezubere nke ọma 38-40 L/D screw Ọdịdị yana oghere nri nri na-eme ka mgbaze na-agbaze na mmetụta plastik ka mma. Igbe gia dị elu, ike dị elu na-eme ka ọrụ ahụ kwụsie ike. Akpụkpọ a na-apụ apụ na aka uwe nha na-ewere usoro nhazi kachasị elu. PLC na-agbanwe ugboro ugboro na-achịkwa agụụ tank tank, traktọ ọtụtụ traktị servo-driven, na ngwa ngwa na-enweghị mgbawa na-eji usoro njikwa arọ mita. The ọkpọkọ extrusion arọ bụ ihe ziri ezi.

HDPE ọkpọkọ bụ ọkpọkọ rọba na-agbanwe agbanwe nke a na-eji thermoplastic elu-njupụta polyethylene nke a na-ejikarị eme ihe maka mmiri dị ala na nnyefe gas. N'oge na-adịbeghị anya, HDPE ọkpọkọ nwetara ọtụtụ ojiji maka iburu mmiri mmiri, ihe mkpofu dị ize ndụ, gas dị iche iche, slurry, mmiri ọkụ, mmiri mmiri, wdg. The siri ike molekụla nkekọ nke HDPE ọkpọkọ ihe na-enyere ya aka iji maka elu-nrụgide pipelines. Ọkpụkpụ polyethylene nwere ogologo akụkọ ọrụ ama ama maka gas, mmanụ, Ngwuputa, mmiri na ụlọ ọrụ ndị ọzọ. N'ihi ịdị arọ ya dị ala yana nguzogide corrosion dị elu, ụlọ ọrụ ọkpọkọ HDPE na-eto nke ukwuu. N'afọ 1953, Karl Ziegler na Erhard Holzkamp chọtara polyethylene dị elu (HDPE). HDPE ọkpọkọ nwere ike ịrụ ọrụ nke ọma na oke okpomọkụ nke -2200 F ruo + 1800 F. Otú ọ dị, a naghị atụ aro iji HDPE Pipes mgbe okpomọkụ mmiri dị elu karịa 1220 F (500 C).

A na-eme pipụ HDPE site na polymerization nke ethylene, nke sitere na mmanụ. A na-agbakwunye ihe mgbakwunye dị iche iche (stabilizers, fillers, plasticizers, softeners, lubricants, colorants, flare retardants, blowing agents, crosslinking agents, ultraviolet deradable additives, wdg) na-agbakwunyere na-emepụta ikpeazụ HDPE ọkpọkọ na components. A na-eme ogologo ọkpọkọ HDPE site na kpo oku resin HDPE. Mgbe ahụ, a na-ewepụ ya site na anwụ anwụ, nke na-ekpebi dayameta nke pipeline. A na-ekpebi oke mgbidi Pipe site na nchikota nke nha ọnwụ, ọsọ nke ịghasa, na ọsọ nke traktọ na-ebupụ. Ọtụtụ mgbe, a na-agbakwunye 3-5% carbon ojii na HDPE iji mee ka ọ na-eguzogide UV, nke na-eme ka ọkpọkọ HDPE ghọọ oji na agba. Ụdị agba ndị ọzọ dị mana anaghị ejikarị ya eme ihe. Ọkpụkpụ HDPE nwere agba ma ọ bụ nke nwere eriri na-abụkarị 90-95% ihe ojii, ebe a na-enye eriri agba na 5% n'èzí.